Thermochromic ink(ST Color)

- Example

-

label

coaster

Teaching material

Image: This handy label notifies you when beer has chilled to perfection.

ST Color is a reversible thermochromic ink

which was developed under Kuboi’s unique technologies

ST Color is a reversible thermochromic ink which was developed under Kuboi’s unique technologies, and which repeats color appearance and color disappearance in a specific temperature zones. ST Color can add high value to the products, for example, letters disappear with the body temperature if touched on the printed surface, or letters appear when cooled down.

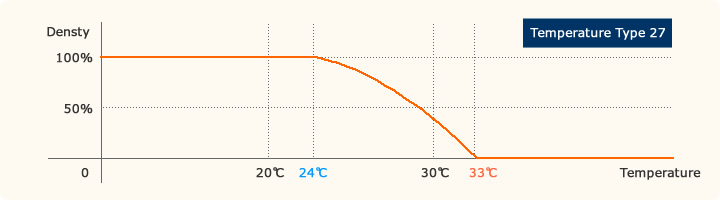

Temperature Type

| Temperature type | Temperature of complete color appearance |

Temperature of complete color disappearance |

Remarks |

|---|---|---|---|

| 15 | 11C | 19C | For refrigerator and cold drinks |

| 27 | 24C | 33C | For body temperature |

| 35 | 27C | 36C | For bath |

The ink color density attains to 100% at the temperature of complete color appearance or lower. The color density gradually decreases when heated, and it comes to zero at the temperature of complete color disappearance or higher.

Tolerance: 1C

Number of colors

Three colors in total (pink, blue and black)

(Some colors are not prepared for some ink types. Please contact us in advance.)

| Silk printing | color | offset printing |

|---|---|---|

| orange | no settings | |

| pink | ||

| blue | ||

| black |

Weather Resistance

| Item | Level Evaluation* |

Comment |

|---|---|---|

| Heat resistance | 5 | Normal up to 120ºC/30 minutes (as color material) |

| Light resistance | 1 | Very weak. So please verify when determining the specifications of printed matter. |

| Solvent resistance | 2 | The ink may become yellow, lose functions, or bleed out. |

*5 (strong)-3 (ordinary) - 1 (weak)

Types of Ink

Three colors in total (pink, blue and black)

(Some colors are not prepared for some ink types. Please contact us in advance.)

| UV screen ink: | For paper and film |

|---|---|

| UV flexo ink: | For paper and film |

| Sheet-fed offset ink: | Oxidative polymerization-type ink for paper |

| UV offset ink: | For paper and film |

Recommended Printing Conditions and Cautions

Three colors in total (pink, blue and black)

(Some colors are not prepared for some ink types. Please contact us in advance.)

| Screen printing: | Please use an 80-150 mesh screen, and fully dry (cure) the ink. |

|---|---|

| Flexographic printing: | Please use 80-200 Lpi anilox. |

| Offset printing: | The water allowance is small for both of sheet-fed ink and UV ink. Please squeeze the dampening water before starting the printing. In particular, if you use a UV ink, please add 10-15% of IPA to the dampening water, and squeeze the dampening water to the utmost limit. Since the ink color density is small, apply the ink as thickly as possible. (The standard amount of ink application is 4-5 g/m2 when using a PS plate, and 5 - 8 g/m2 when using a resin plate.) When using a resin plate, please use a plate which is softer than the standard one. (Example: nyroprint®WF95 H) |

* This document was prepared based on examination of data that is considered to be the most reliable in our company, which are, however, examples cited for your reference. Users are requested to examine them before using. The figures stated above are standard values in our company, but not guaranteed values.

* When using the product, please verify its suitability for your conditions of use.

* Patents are applied for a variety of printed matters and novelty goods using these special inks. We do not guarantee that the examples of usage and the text of this document do not infringe any patent.

* Before handling or using these inks, please read the Material Safety Data Sheet (MSDS).

*The product is subject to change without prior notice for the improvement.